Mechanical

JV COMPANIES

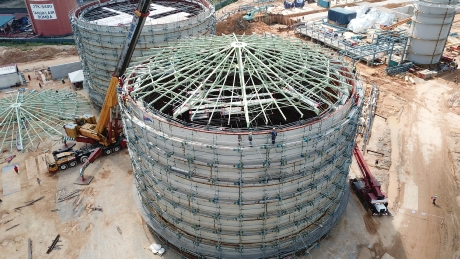

Storage Tank erection scope:

Design, Pre-

Methods used: API-

Storage Tanks – Detailed Scope:

• Design and Construction of Storage tanks

• Preparation of Construction drawings and submission for approval.

• Procurement of Materials such as plates, pipes, pipe fittings, flanges and fasteners.

• Carryout stage wise inspection in presence of Client.

• Mechanical guarantee against workmanship and materials.

• Inspection and Testing.

• Hydro-

• Positive Material identification

• Picking and Passivation

• Platform and Ladder Clips, Insulation cleats

• Surface preparation and painting

• Final as Built Dossier.

Storage Tanks-

Up to 300 ft Día (91m)

• Capacity up to 80,000 m3 (500,000 bbl.)

• Cone/flat/floating roofs

• CS tank material

• Foundations & retaining walls

• Insulation

• Cathodic protection

• Heat relieving.

Our proven track record is our ability to set‐up, organize, and run a pipeline in a competent and professional manner, ably assisted by our capable workforce who has many years of experience of working in the pipeline industry.

We can offer pipeline construction, gas supply pipeline construction, district heating pipeline construction, fire mains, industrial pipelines, plant construction.

Also, we can provide Specialists in pipeline safety (with non-

pressure tests and safety assurance, Human and environmental safety is the critical point in the construction and operation of pipelines for our clients, high-

Cleaning of hydrocarbon tanks allows for full and safe access of tanks for inspection and maintenance purposes. It increases the dynamics of operational safety at the storage location. In order to maximize the lifetime or total service life of a tank, sufficient maintenance should be undertaken to counteract degradation mechanism such as corrosion or deposition. Cleaning of the tank is recommended even when one decides to change its storage content, so as to prevent the mixing of one content with another. Cleaning plays an important role in the maintenance of tank and it potentially helps in increasing the service life of the tank; however, it requires the tank to be out of commission for a certain period of time. Moreover, the cleaning process in itself can be a potentially hazardous procedure both for the environment and human life

Cleaning (Traditional Tank Cleaning method):

We can provide and perform Traditional Tank Cleaning method as follows:

• Implementation of the safety procedure in the worksite and inside the tank, by means of explosion proof forced ventilation systems, either pneumatic or electric;

• Sucking up of the liquid slop by means of a vacuum truck, or by pneumatic or volumetric pumps, set in motion by hydraulic or electric ATEX certified motors;

• Manual removal of solid sludge, carried out by operators provided with all the necessary protection devices and specific equipment to enter the tank (hydraulically actuated volumetric pumps and manual non-

• Tank internal final washing with high pressure water pump, additivities with environment compatible solvents.

• Channeling of the cleaning water into Wastewater Treatment Plant

• Issue of a Gas Free Certificate by authorized external professionals

Sand blasting is a wide range of items ranging from structural steel, I-

Sandblasting allows us to remove rust, mill scale, old coatings, and contamination in preparation for a high-

A different type of abrasive media can be used during the blasting process includes: glass beads, ground glass, aluminum oxide, black beauty slag, steel grit, steel shot, each possessing unique benefits and features.

LTCST company can provide Painting and coating – onshore and offshore industrial-

We are involved in providing Turnkey Services to our customers. also offering products are highly durable, reliable, long functional life and more efficient. We manufacture these products using standard grade raw material that buy by the certified vendors of the markets who have excellent experience in their field. Quality of product is the main objective of our company. We are efficient to satisfy our clients completely. Our professionals have deep knowledge and experience in their domain that helps in producing best quality products which mostly satisfied the customers. By providing best quality products to our customers, we have maintained a trustworthy relationship with our valuable clients and other organization in the market.

Libya Technology CO

Tripoli Libya

Info@ltcst.ly

| materials |

| Mechanical |

| Electrical |

| Civil |